Diffraction

To investigate atomic and/or magnetic structures

Neutron diffraction experiments determine the atomic and/or magnetic structure of a material. This technique can be applied to study crystalline solids, gasses, liquids or amorphous materials.

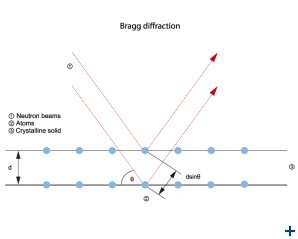

Neutron waves are diffracted by the consecutive layers of atoms in a crystal – this provides information on the structure of the crystal. © MLZ

Neutron diffraction is a form of elastic scattering where the neutrons exiting the experiment have more or less the same energy as the incident neutrons. The technique is similar to X-ray diffraction but the different type of radiation gives complementary information. A sample to be examined is placed in a beam of thermal or cold neutrons and the intensity pattern around the sample gives information of the structure of the material.

Because neutrons are uncharged, they interact only with the nuclei of the specimens atoms. This leads to a very low absorbance and therefore high penetration depth (several centimetres) for most materials. In additions, the beam cross-sections are very large. This means, that measurements on larger samples or complex sample geometries are possible than it is the case with X-rays.

The following aspects make diffraction by neutrons a valuable tool for materials analysis:

- Non-destructive application

- Phase sensitivity

- In most cases allowance of the determination of absolute values and the sign of stress tensor components

- Often weak absorption of neutrons and high-energy photons, which allow extension of the information depth from the surface to the bulk

- High variability of neutron energy

- Various possibilities of defining the gauge volume

Residual stress and strain analysis

Compressor disc used in a turbine

Residual stresses are mechanical stresses present in a workpiece or a component, which is not influenced by external forces or heat gradients. Residual stresses are present in nearly all materials and result from deformations, heat treatments or structural changes (phase transformation). Uneven cooling in castings or welds also leads to significant residual stresses.

Residual stresses, superposed by external load during service conditions of the material can lead to premature failure of the components. In other cases, residual stresses are generated on purpose to obtain materials with special features. This technique is called residual stress engineering.

Texture analysis

In general, metallic, ceramic and some plastic samples consist of polycrystalline materials. One of the basic parameters to characterize these materials is crystallographic texture, since it describes the orientation distribution of the crystallites in the sample.

The orientation of the crystallites has strong influence on the properties of the material, since the crystallographic structure leads to anisotropic properties of single crystals.

This leads to texture dependent properties of a material regarding e.g., Young’s modulus, electric conductivity, thermal expansion, plastic anisotropy or magnetic behaviour.

Case Studies

- Investigation of residual stresses in new materials for the development of aircraft turbines

- High-Strength Aluminium Alloys: investigating stresses for improved casting

- Understanding the structure of aged Ni-Cr based alloys

- Stress analysis of hydroxyapatite coatings for orthopaedic implants

- Performances of Li-ion battery: investigating lithium ion movements

- Composite compounds for hydrogen storage

- Examining a ceramic-to-metal brazing of specific cutting tools

- Reducing CO2 in Al production

- Non-destructive stress mapping to address challenges in additive manufacturing

Sources

- ISIS: http://www.isis.stfc.ac.uk/instruments/neutron-diffraction2593.html

- W. Reimers (editor), A. R. Pyzalla (editor), A. K. Schreyer (editor), H. Clemens (editor), Neutrons and Synchrotron Radiation in Engineering Materials Science, Viley VCH, 2008, p. 245.