Germany: Design of a high-pressure cell for in situ neutron scattering investigations of hydrogen storage materials

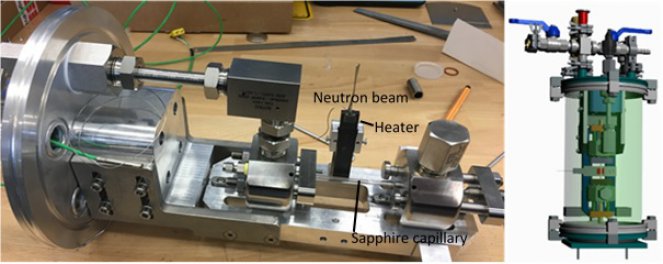

Figure 1: Photo of the fully equipped high pressure hydrogen cell (at STRESS-SPEC).

Klaus Pranzas, Neslihan Aslan, Christian Horstmann, Oleg Kotlyar, Oliver Metz, Claudio Pistidda, Martin Dornheim , Sebastian Busch, Martin Müller from Helmholtz Zentrum Geesthacht (HZG) and Wiebke Lohstroh from the Technical University of Munich (TUM) have been developing a new high-pressure cell for in-situ neutron scattering for their research into hydrogen storage materials.

The motivation

Currently, scientific progress is being made in hydrogen storage solutions. Solid metal hydrides absorb and release hydrogen reversibly and safely; are easily transportable and can hold high volumes of hydrogen gas ready for use. Development of these hydrogen storage materials could get us closer to a Hydrogen economy i.e. where electricity and transport are powered by renewably produced hydrogen, thus cutting the world’s carbon footprint and reducing our reliance on fossil fuels.

An interesting hydrogen storage material currently being explored by the scientific team at HZG is the metal hydride Ca(BH4)2-Mg2NiH4. However, the uptake and release of hydrogen occurs at high H2-pressures and temperatures of about 100°C. In fact, in industrial applications, pressures up to 700 bar H2 are already being used in current devices. Trying to understand these absorption and desorption processes as they happen involves observing the samples in situ at these high temperatures and pressures.

Due to the sensitivity of neutrons towards hydrogen, neutron techniques provide important information for optimization of hydrogen storage systems. Neutron diffraction, Small Angle Neutron Scattering (SANS) and inelastic neutron scattering could tell us more about the phase transformations, nanostructures, dynamic properties and hydrogen diffusion during the hydrogen desorption and absorption processes.

For Task 7.3 in SINE2020’s Sample Environment work package, HZG have developed a high pressure cell suitable for the in situ study of hydrogen storage materials designed for pressures up to 700 bar and temperatures up to 500˚C. This prototype cell should be very flexible so it can be used on as many different European neutron facilities and instruments as possible.

Figure 2 Left: Photo of the cell with some parts removed for better clarity. Right: Setup of the cell together with the aluminium protection tube and the corresponding connections.

The device is a further development of a high pressure cell already used for in situ X-ray diffraction techniques. It needed to be adapted for use with neutrons, for example by making it large enough to fit a neutron beam. The sample is positioned in a Sapphire tube (Figure 2, left). Sapphire is stable at the required pressure and temperature conditions and is also transparent to neutrons and inert to hydrogen. The cell can fit into a standard glove box opening. This is required as many samples are sensitive to moisture and oxygen and need to be loaded under inert gas atmosphere. The cell can be moved easily and mounted both vertically and horizontally which is important for the compatibility with many neutron instruments.

Of course safety considerations play an important role. The hydrogen volume in the cell is kept to a minimum. The pressure cell is surrounded by an aluminum protection tube (Figure 2, right and Figure 3). The volume in this tube is constantly flushed with inert gas during operation to avoid the formation of an explosive H2/O2 gas mixture in case of a cell leakage. If there is a leak or the temperature gets too high, the heating switches off automatically.

Figure 3: Cell with aluminium protection tube.

The results

Once constructed, this high pressure cell was ready to be tested. Neutron diffraction and scattering measurements were performed on three instruments at the FRM II in the Heinz Maier-Leibnitz Zentrum (MLZ): STRESS-SPEC, SANS-1 and TOFTOF

SANS-1: A good signal-to-noise ratio was achieved and the structural changes of the metal hydride nanostructure could be observed in the hydrogen desorption processes.

STRESS-SPEC: Diffraction peaks could be observed, although the 3 mm Sapphire capillaries used were too small, so the signal-to-noise ratio was low.

TOFTOF: Dynamic processes were investigated by inelastic neutron scattering, but the measurement revealed that capillaries with larger diameters up to 7-10 mm should be used.

The measurements provided important information for optimization of the high-pressure cell and the experimental procedure. The safety measures put in place also proved successful.

The team would also like to acknowledge Konstantin Kamenev (CSEC), André Heinemann (MLZ) Burkhard Annighoefer (LLB), Stefan Klots (IMPMC), Mark Kibble (ISIS/STFC), Dirk Siemers, Thorsten Böttcher, Sven Kleeband, Dennis Heims, Axel Schilf (HZG) for their contributions.

More information on the work of the scientific team will soon be available in the article describing the cell and first results when it is published*. The cell and the corresponding set-up will be further optimized and employed for the investigation of hydrogen storage materials using neutron scattering methods.

References:

*N. Aslan et al., High-pressure cell for in situ neutron studies of hydrogen storage materials, Journal of Neutron Research (submitted)

On the pathway to novel hydrogen storage materials

A hydride composite featuring mutual destabilisation and reversible boron exchange: Ca(BH4)2–Mg2NiH4

Article Acknowledgements: Klaus Pranzas and Neslihan Aslan HZG

Back to The Road to the ESS

Other articles: HZG, MLZ/TUM, PSI Hosted the High Pressure Cells kick-off meeting, Sample Environment, Next-generation anvils for the Paris-Edinburgh cell